By RYO SUGANUMA/ Staff Writer

August 21, 2023 at 07:00 JST

NAGANO--Leather is becoming a problem as some people won’t wear animal hide and synthetic leather comes from crude oil.

But now there’s an environmentally friendly leather from agricultural sources.

Those producing it come from the farms of Shinshu, an upland region that roughly matches the boundaries of Nagano Prefecture.

In May, an apple leather was unveiled by Sorena, a local fashion accessories company.

“I would like to make this a product that represents Shinshu and one that we can proudly showcase to the world,” said Yuri Ito, the company’s president. Ito was speaking to reporters at the prefectural government office.

Leather and fur have taken a hiding in recent years. Animal welfare is no longer the realm of activists but is affecting mainstream consumer choices, as are environmental concerns.

In 2017 fashion house Guccio Gucci, S.p.A. announced that it would cease using fur. The move was mirrored across the fashion industry, as designers said they, too, would halt the use of leather and fur.

Therefore, there is a market for faux leather--a synthetic fabric with similar appearance and properties. But it is made from petroleum-derived materials such as polyurethane.

Ito learned in 2021 that environmentally friendly leathers made from apples were being produced overseas.

“There is no reason we can’t do it in Japan as well,” she said.

APPLE LEATHER

Nagano Prefecture is Japan’s second largest apple producing region. Ito wanted to use Shinshu’s resources, in particular, the wastes produced by the apple industry.

Her idea was selected for the prefectural government’s start-up business support program for fiscal 2021.

Sorena develops apple leather in collaboration with two entities. One is Iizuna town, an apple-producing region in the northern part of the prefecture. The second is a manufacturer of synthetic leather.

Iizuna is famous for its apple juice and cider production. It generates about one ton of apple pomace per day. Pomace is the pulp of peel, pips and pith that remains after an apple has been pressed for its juice.

The company dries and powders the waste, then mixes it with synthetic resin. It adds this to a cotton base material to make leather.

This way, more than half of the raw materials used to make apple leather are derived from plants.

“Farmers grow apples with pride,” Ito said. “I would be pleased if our leather not only contributes to realizing a sustainable society but also helps (consumers) get to know such people.”

What does the result feel like? The texture is no different from ordinary synthetic leather.

Consumers already can purchase apple leather products. Tote bags, wallets and other items are available for online purchasing from the company.

MUSHROOM LEATHER

Mycl Japan Co. of Komoro city in the same prefecture is developing a leather using mushroom material. Nagano Prefecture is the nation’s largest producer of mushrooms.

“The mushroom leather we produce is made from 100 percent natural materials,” said Keita Inui, Mycl Japan’s president.

The leather is made from mycelium, a fluffy tissue that spreads from the base of mushrooms as they grow.

The company uses its own techniques to grow mycelium into a mat. It takes one to two months to form mushroom leather.

Mushroom leather feels similar to genuine leather. It has a cream color with brownish and blackish patches. Sheets of it measure 60 centimeters by 30 cm.

“Each piece has a unique pattern, which is characteristic of natural materials,” Inui said. “People should appreciate it as a one-off product.”

Mycl Japan was established in July 2022 as a joint venture with four companies.

One is a company in Singapore that holds a patent for manufacturing technology.

Another is Salai International Japan Co., also based in Komoro city, which exports technology for mushroom farms.

The third partner is Chikumakasei Co. of Chikuma city, Nagano Prefecture, which grows and sells mycelium.

Fourthly, Sakato Sangyo Co. in Gunma Prefecture is a dealer in cultivation materials and machinery.

Mycl Japan is looking at growth opportunities within Japan. This year, it bought and began renovating a former Komoro senior citizens’ welfare center. It plans to use the building as a factory.

Separately, a cultivation building will be completed by the end of September. The company aims to produce 45 square meters of mushroom leather per week. It will start supplying clients in October.

Manufacturers that have expressed interest include apparel and furniture manufacturers. A bag brand in Tokyo has already decided to use the material.

But Mycl Japan has ambitions beyond growing the leather. It aims to launch its own brand.

Moreover, the company’s president notes that the fabric may offer new opportunities for hard-up mushroom growers.

“Many mushroom farmers are facing financial difficulties. Some cannot continue their businesses,” Inui said. “Our mushroom leather is a new material that can be produced utilizing basic mushroom cultivation techniques.”

He added: “In the future, we would like to franchise the business and have many farmers participate. It would aim for a mutually supportive relationship in which we help each other.”

A peek through the music industry’s curtain at the producers who harnessed social media to help their idols go global.

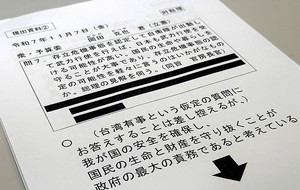

A series based on diplomatic documents declassified by Japan’s Foreign Ministry

Here is a collection of first-hand accounts by “hibakusha” atomic bomb survivors.

Cooking experts, chefs and others involved in the field of food introduce their special recipes intertwined with their paths in life.

A series about Japanese-Americans and their memories of World War II