By HAYATO SAKATA/ Staff Writer

September 6, 2021 at 18:50 JST

TAKAMATSU--The driver of a 2-ton crawler excavator was fatally crushed when the vehicle tipped over while he was trying to maneuver it from a truck bed by himself, having lowered its arm and bucket to the ground for support.

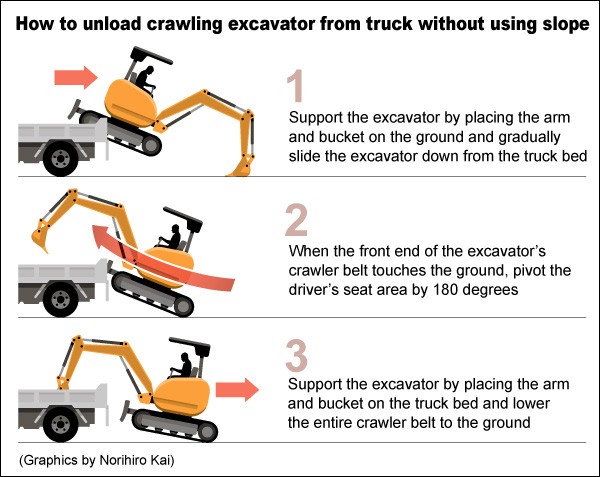

Local labor authorities said the way the driver tried to unload the heavy vehicle was “unexpected” and “dangerous.”

But the do-it-alone method appears to have become the norm at construction sites over many decades. Videos on how to perform the task without a slope or other means are posted on the internet.

The labor ministry’s Takamatsu labor standards inspection office accused the president of the construction company in Takamatasu of violating the industry safety and health law and referred the case to prosecutors in August.

Regulations for unloading and loading procedures call for at least one worker other than the driver to be present to ensure safety when a machine or cargo weighs 100 kilograms or more.

But labor officials believe no one was on hand when the fatal accident occurred on the premises of the construction company here on June 1.

They also said the driver, who was in his 40s, was operating a crawling excavator that weighed around 2 tons.

When he tried to dismount the vehicle from the back of a truck, the vehicle lost balance and tipped over.

The driver was thrown out of his seat and crushed under the excavator’s arm.

The driver had more than 20 years of experience operating heavy machinery, according to labor officials.

The loading platform of the truck was 80 centimeters above the ground.

When an excavator is loaded and unloaded, it is common to deploy a dedicated truck that can slide its platform to the ground to form a slope, allowing the vehicle to be driven.

When such trucks are not available, workers are supposed to fix a board to the back of a truck or build mound on the ground for the procedure.

But in this particular case, a dedicated vehicle was not used. There was no board or mound built at the scene, either, labor officials said.

A worker in the construction industry said the method the driver used had been common practice at sites for decades.

“It is cheaper and quicker than using a board,” he said. “Personally, I am scared to do that because the vehicles tilt significantly.”

A number of videos are posted on YouTube, explaining how to load and unload alone. One of the videos is titled “act of God.” One video got more than 1 million views.

A man who rents out heavy machinery in the Kansai region and uploaded a video on safety steps said he did so to teach the proper way of doing things to avoid mistakes that can prove fatal. He recommends that operators used a dedicated vehicle at all times.

“I know from experience that novice operators took it for granted that they learn the ropes of loading and unloading alone by watching experienced operators do the work,” he said.

The man said many young people go online to seek instruction on the do-it-alone method.

When contacted for comment by The Asahi Shimbun, the president of the construction company said he had never recommended that method.

“The driver might have done it so as not to cause trouble by asking others for help in ensuring the procedure went ahead safely and smoothly,” the 44-year-old president said in a statement. “I have instructed our employees to make sure they use a dedicated truck for safety.”

A peek through the music industry’s curtain at the producers who harnessed social media to help their idols go global.

A series based on diplomatic documents declassified by Japan’s Foreign Ministry

Here is a collection of first-hand accounts by “hibakusha” atomic bomb survivors.

Cooking experts, chefs and others involved in the field of food introduce their special recipes intertwined with their paths in life.

A series about Japanese-Americans and their memories of World War II